DRYER TECHNICAL FOCUS

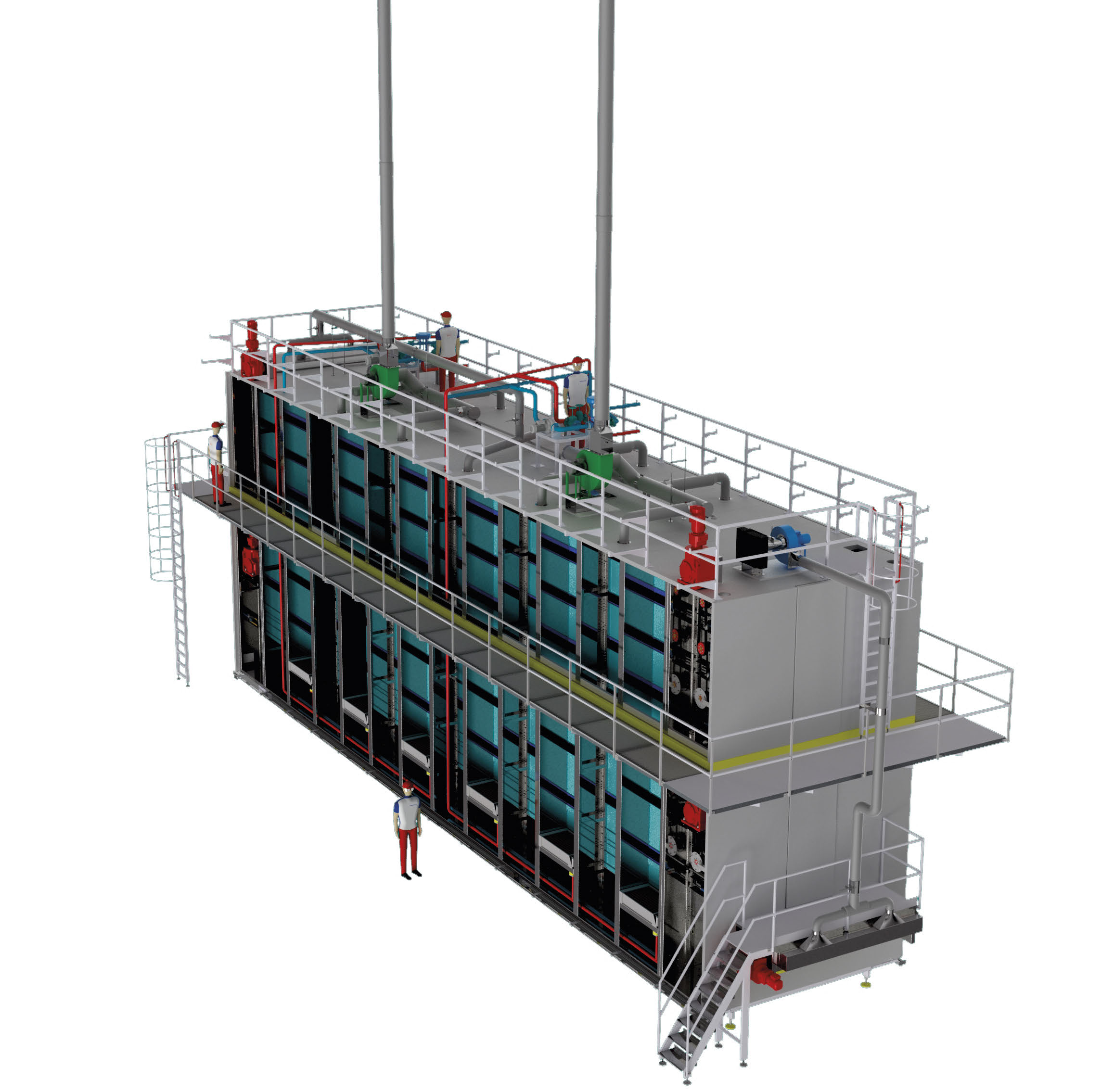

PDT-HT technology for long pasta

Progressive Drying Technology – High Temperature.

Progressive Drying Technology that can reach High Temperatures at the end of pre-drying zone and at the beginning of the drying zone, which is specifically designed for Long Pasta lines, to ensure correct drying of the product during the whole process.

Continuous ventilation and tempering treatment in every zone of the dryer.

Excellent air circulationto ensure homogeneous drying in the whole length.

Different drying zones to control the whole process, increase energy efficiency and reduce the dryer surface.

TDU-HT technology for short pasta, nest pasta and snack lines

Three Drying Technology – Hight Temperature

Three-Zone drying technology that can reach high temperatures during pre-drying. Easy-to-manage and highly versatile dryer for all types of pasta.

Continuous ventilation and tempering treatment in every zone of the dryer.

Pre-dryingsection, Dryingsection, Stabilizingsection.

Maximum control of the drying process parameters.

Heat recovery from high temperature zones to save energy.

Rotary dryers for couscous, small size pasta and snack pellets

Drying technology that features conveyor augers linked to a drum conveyor, to ensure continuous movement of the product during the whole drying stage.

Rotary blowers with high capacity and prevalence ensure excellent air circulation for a correct drying treatment.

Rotary dryers are perfect for couscous, small size pasta and snack pelletss

The drying parameters are controlled via PC and PLC, by means of probes, sensors, proportioning valves, extractors and inserters, to guarantee high quality standards in drying.

Static dryer

Very good starting point for new pasta factories, for drying special types or for top quality artisanal production.

Static dryers are designed to offer aconstant and continuous flow of air with recovery treatment and excellent air circulation through all frames.

Provided with probes and sensors for temperature control, they allow energy saving.