Distance-Cut Pellets

Benefits

Mixer

Snack Pellets are made using different raw materials, such as cereals(wheat, corn, rice), legumes(chickpeas, lentils), tubers(potatoes, tapioca), fibersfrom vegetables and cereals… These raw materials, usually in the form of flour, are pre-mixed in the mixer according to the desired product.

Stainless steel mixer, provided with hopper to collect the mixed product, extraction and dosing auger, vibrating cleaner and conveyor of the product from the Extruder, all integrated in the production line control system.

Ladders, railings and door to easily access for cleaning.

Benefits

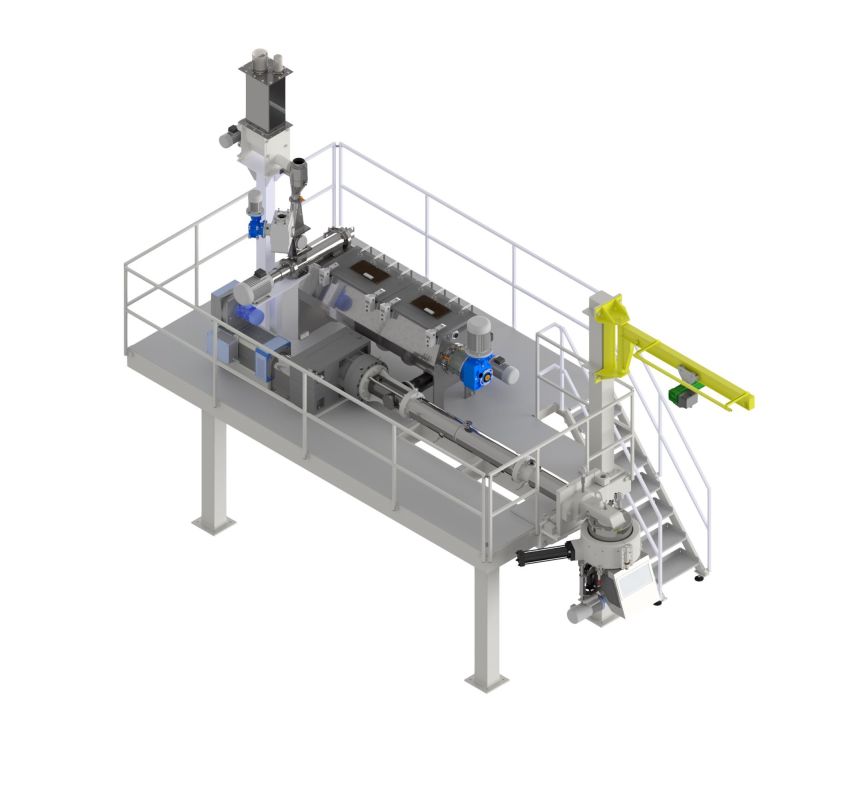

Cooker Extruder

The Cooker-Extruder is used to mix raw materials with water and treat them both thermally and mechanically to achieve the molecular structural changeneeded to correctly transform the dough into pellets.

Possibility to mix the product to be extruded under Full Vacuum to improve the characteristics of the pellets according to the raw materials used.

The main features of this machine are: great production flexibility for different types of mix, cylinder and extrusion screw divided into several sections to allow the correct technological treatment, cooking section controlled with high-temperature thermal fluid.

Other features are: effective control of the temperatures by means of proportioning valves and circulation pumps with retro-action according to the actual temperature of the product in the cooking phase, easy management through PC and PLC with SCADA User Friendly,easy cleaning and maintenance with motorized trolley for screw extraction and hoist to lift the die plates.

Benefits

Inking and Cutting

Snack pellets are usually made of cereals, potatoes or legumes. Texture, colour andcrispy level may vary according to the raw material and the extrusion recipe.

The head pressure affects product thickness and its texture. Once the product is extruded in pellets, it is cooled on a product collection belt, it is inked in the case of Bacon Strips and is finally cut in a dedicated cutter.

Benefits

Inker

This machine is used to ink the strips of pellets, for producing Bacon Strips or a similar type.

The machinery is provided with inking roller made of food-contact plastic, that allow a precise flow of flakes preventing them from attaching to the roller. Tank and recirculation pump group for the ink to keep a constant level in the inking tray.

The inking rollers are moved by an invertercontrolled motor. Every part that touches the product is made of Stainless Steel..

The machine is mounted on wheels to be movable for routine operations of extruder screw extraction.

Benefits

Cutter

The cutter receives the pellet strips on a rubber conveyor roller and conveys them in the cutting group. The motor that controls the roller in provided with an inverterthat can be adjusted from PC and PLC

Cutting group made of blades mounted on a robust shaft for a precise cut, driven by the inverter to adjust the cutting length according to the requested shape.

The machine is mounted on wheels to be movable for routine operations of extruder screw extraction.

Benefits

Shaker and pre-drying unit

The shaker and pre-drying unit represents an important technological phase when producing Pellets, since it guarantees a correct pre-drying of the pellets just extruded, thus preventing them from sticking to each other.

The machine is made of vibrating stainless steel trays with variable vibratingfrequency,robust structure, fans, air extractors and heat exchangers that are properly sized and have high efficiency, for a correct pre-drying of the product.

Easily removable insulating panels for thorough cleaning, maintenanceand sanificationof the machine.

Benefits

TDU technology Dryer

The dryer is used to dry the pellets homogeneously so as to guarantee a high-quality productin the following processing phases (expansion by means of fryers, toasters, etc..).

High-temperature drying (TDU-HT technology) with ventilation and tempering with light touch and continuous passage.

Strong flexibility and high efficiency in drying different types of pellets. The dryer features an energy re-use system during the various stages of drying, which entails energy saving and production costs reduction.

Correctly sized motor reducer, extractors, fans, heat exchangers, pumps, proportioning valves, and continuously monitoring of the drying parameters through high-quality temperature and humidity sensors. Frame and panels are entirely made of Stainless Steel.

Benefits

High-efficiency Cooler

The cooler is used to bring the product to room temperature to ensure pellets stability after some time.

High efficiency with dewpoint control to ensure no condensation and allow a correct stabilization of the product output.

Automatic product temperature and humidity control.

Stainless steel insulating panels that can be easily removed from the frame, for thorough cleaning, maintenanceand sanitizationof the machine.

Quality

High manufacturing standard

Flexibility to produce different types of pellet.

Easy cleaning and maintenance

Modularity and flexibility to meet specific client’s requests

Solid frame and panels entirely made of stainless steel

Complete automation and control of the line via PC and PLC.